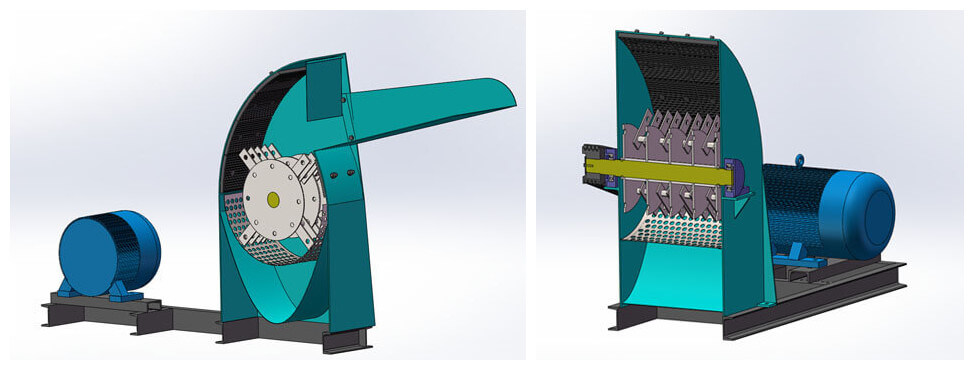

Introduction to Wood Hammer Crusher Machine

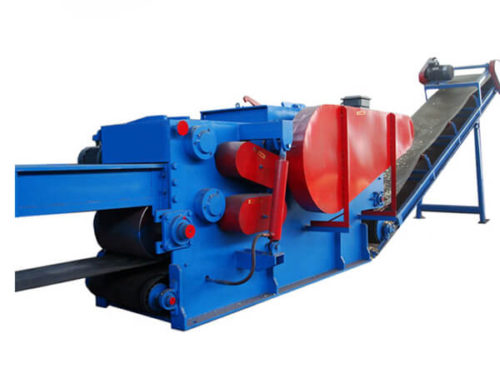

Being one basic wood processing equipment in wood pellet plant, wood hammer crusher machine is mainly adopted to grind various kinds of biomass raw materials into the required fineness. After crushing, the product can be used for wood pellet, wood briquette and wood composite board production. As one professional wood hammer mill manufacturer, we have developed a series of hammer mills to meet different requirements.

Application of Wood Hammer Crusher Machine

Wood hammer crusher machine can be used to grind a wide range of particle sized and various raw materials, such as cotton stalk, wood chips, wheat straw, palm kernel, wood barks and some agricultural wastes. After crushing, the raw materials are uniform in size for further processing.

Features of Wood Hammer Crusher Machine

1.Advanced design and simple structure makes the machine have stable performance and good quality.

2.Different requirements of sizes can be met by adjusting the gap between the screen and hammer.

3.Wood hammer crusher is equipped with various screen sieve for customer to choose according to raw material grinding requirement.

4.Raw materials after crushing can be collected and transported with an air blower.

5.Final crushed materials are in uniform fineness because the hammers and the clearance between hammers and screens are reasonably arranged.

Tips on Operation of Wood Hammer Crusher Machine

1.Regularly check the component and connection parts to see if there is loose phenomenon. If yes, tighten them right away.

2.Adding lubrication oil regularly to ensure the smoothly and stable operation of the machine.

3.During wood hammer crusher machine working process, you should also pay attention to its condition to see whether there is strong vibration, noise or too high temperature. If anything abnormal happens, stop and check immediately.

Technical Parameters of Wood Hammer Crusher Machine

| Model | Power(kw) | Capacity(kg/h) | Dimension(mm) | Weight(kg) |

| HM200 | 5.5 | 300-350 | 900*500*800 | 260 |

| HM300 | 7.5 | 400-500 | 1100*550*850 | 350 |

| HM400 | 11 | 600-800 | 1250*650*1000 | 450 |

| HM500 | 22 | 900-1000 | 1400*780*1250 | 750 |

| HM600 | 30 | 1500-2000 | 1600*850*1350 | 900 |

| HM800 | 45 | 2000-3000 | 1750*900*1550 | 1300 |

Leave A Comment