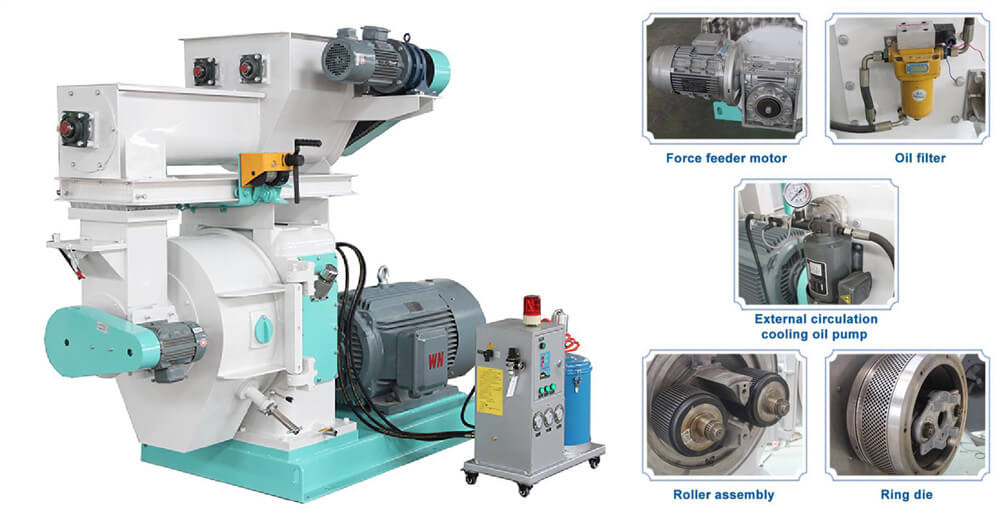

Introduction to Ring Die Wood Pellet Mill

Ring die wood pellet mill is used to press biomass residues into pellets, including wood residues (i.e. sawdust, wood chips, wood shavings, etc.) and agricultural resides (i.e. rice husk, rice straw, wheat straw, sunflower husk, etc.). The ring die pellet mill of MKLH series is modified based on the characteristics of biomass pelletizing.

Application of Ring Die Biomass Pellet Machine

It is mainly used for pelleting the ground biomass residues like sawdust, pasture, straw, etc. Models of this series are equipped with ring dies whose holes are with diameters of 8mm, 10mm and 12mm. The results show that the wood pellets of these sizes are more favorable to burn. Of course, the ring dies can be customized according to customers’ requirements.

Features of Ring Die Wood Pellet Machine

1. The machine is composed of special feeder, enhanced transmission parts, as well as specially manufactured ring die, press roller and hold hoop.

2. The gear with high precision is adopted for the main transmission system, making the machine run stably.

3. Quality imported bearing and oil seal are adopted for the feeder, ensuring that the machine can be operated efficiently and stably. In addition, ventilation and cooling system is adopted for the pelleting chamber.

4. Variable-frequency adjustable-speed motor is adopted for the feeder, ensuring the quality of pellets.

5. The pellet mill also adopts serpentine spring coupling, which is of novel, compact and safe structure; and it causes less noise.

Tips You Need to Notice on Operating Industrial Wood Pellet Mill

1. Operator should strictly follow the operation instruction and professional technician’s guidance.

2. The industrial wood pellet mill should be maintained regularly to extend its service life.

3. The operator should be at the working area while the pellet mill is under running condition.

4. Customers should choose appropriate pellet machine according to the raw materials and capacity requirements.

Specification of MKLH Ring Die Wood Pellet Machine

| Model | MKLH350 | MKLH420 | MKLH508 | MKLH558 | MKLH678 | MKLH768 |

| Capacity(t/h) | 0.6 | 1 | 1.5 | 1.8-2 | 3 | 4 |

| Power of the main motor(kw) | 55 | 90 | 110 | 132 | 220 | 315 |

| Power of feed auger(kw) | 1.5 | 2.2 | 2.2 | 2.2 | 3 | 4 |

| Power of feeder(kw) | 0.75 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Inner Dia. of ring die(mm) | 350 | 420 | 508 | 558 | 678 | 768 |

| Rotating speed of ring die(rpm) | 150 | |||||

| Rotating speed of feed auger | 12-120rpm | |||||

| Size of pellets | 6, 8, 10, 12mm, etc. | |||||

| No. of press roll | 2 | |||||

| Noise | ≦86 dB(A) | ≦90 dB(A) | ||||

| Working temperature of die | ≦85 (℃) | |||||

Leave A Comment