Giant king grass is a dedicated energy crop that can be burned in pellet form as a replacement for coal or oil in electric-power plants to produce low-carbon electricity and industrial heat.

2T/H giant king grass pellet production line is specifically used to make giant king grass pellets. The main machines of this pellet plant are hammer mill, rotary wood dryer, two sets of MZLH420 ring die pellet mills, pellet cooler and pellet packing machine.

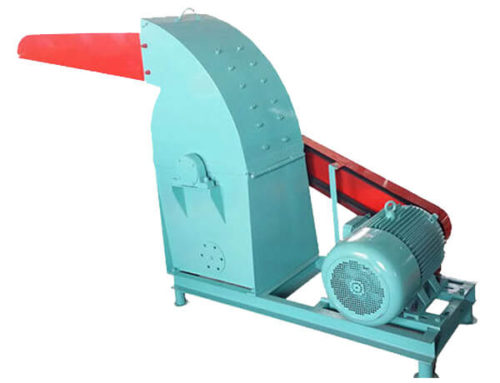

1.Wood Hammer Crusher Machine

Firstly, the giant king grass should be crushed into small pieces because it is 3-5m in height. This hammer crusher machine consist of feed hopper, grinding cell and winding system etc. According to different raw material grinding demands, you can change screening sieve. Furthermore, you can adjust the gap between hammers and screen to realize the coarse or fine grinding. When the raw material be put into the feeding hopper, and then be crushed into powder by rotary flake.

|

|

| Model | HM800 |

| Power | 45kw |

| Capacity | 2-3t/h |

| Dimension | 1750*900*1550mm |

| Weight | 1300kg |

|

|

|

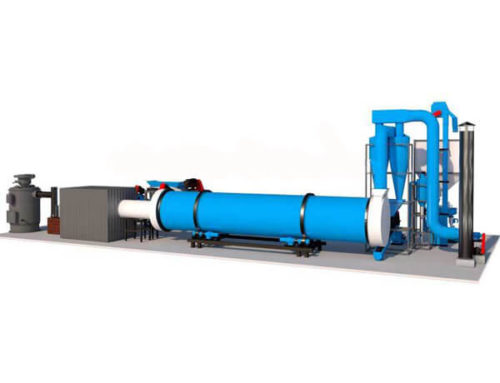

2.Rotary Drum Dryer

The moisture of fresh giant king grass is too high that is approximately 70-75%. This can effect the pellet quality so the rotary wood dryer is necessary. This rotary drum dryer consists of rotating cylinder, transmission device, air fan, shoveling plates and electric control cabinet etc. With the large capacity, low drying costs and low fuel consumption, it can be used for drying a wide range of raw material, such as wood shavings, sugarcane bagasse, sawdust, leaves and marigold etc. Through high temperature and heat air, this rotary drum dryer can reduce the moisture of raw material from 55% to 15%.

|

|

|||

| Model | GX1500 | Capacity | 2-2.2t/h |

| Roller diameter | 1.5m | Roller length | 12m |

| Transmission power | 7.5kw | Air fan power | 18.5kw |

| Cyclone model | SKL1200 | Air lock power | 1.1kw |

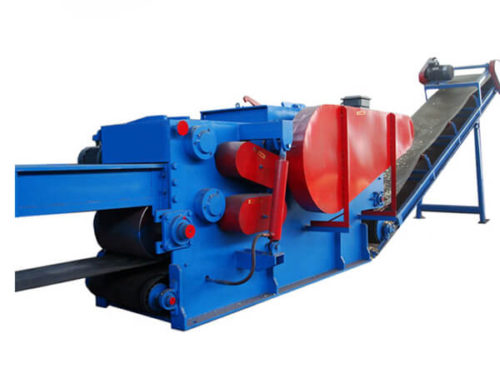

3. Ring Die Pellet Mill

Two sets of MZLH420 ring die pellet mills are the core equipment in this giant king grass production line. It compress the dry crushed material and transform them into a cylinder shape pellet. Compared with flat die wood pellet mill, this ring die pellet mill, equipped with strengthened transmission parts and forced feeder, is more energy efficient. On the one hand, this pellet mill not only use imported high-quality bearings to ensure stable, low-noise, efficient operation but also adopt high-precision gear driving to improve output approximately 20%. On the other hand, the ring die pellet mill use imperative feeding device to ensure a continuous feeding speed. Whereas, if you want to make pellet surface more smooth and solid, this pellet machine also can be equipped with inner oil spraying device.

|

|||

| Model | MZLH420 | Capacity | 1t/h |

| Main motor power | 90kw | Screw feeder power | 2.2kw |

| Ring die inner diameter | 420mm | Ring die rotate speed | 150rpm |

| Roller outer diameter | 165mm | Pellet size | 6mm, 8mm, 10mm etc. |

| Roller quantity | 2 | Roller working temperature | ≤85℃ |

4.Giant King Grass Pellet Cooling Machine

When the pellets are taken from the pellet machine, they are with high moisture content above 16% and high temperature about 70-85%, so the cooling machine is necessary. This cooler can low down pellets’ temperature to 3-5℃ higher than room temperature for preventing mildew and being convenient to store and transport. With counter flow cooling principle and reasonable design, this cooler can prevent pellet breaking and cool particles rationally. Easy operation, low energy consumption, low broken rate and economic space occupation.

|

|||

| Model | SKLN1.5 | Production capacity | 3t/h |

| Cooling volume | 1.5m3 | Cooling time | ≥6-10min |

| Power | 0.75kw | Air lock power | 1.1kw |

5. Giant King Grass Pellet Packaging Machine

This pellet packaging machine can automatically weigh and pack the giant king grass pellets into bags with international advanced PLC technology. It consists of elevator, automatically weighing machine, conveying part and sealing machine. Simple structure, easy operation, accurate weighing and packaging.

|

|

| Model | WDCS-50 |

| Capacity | 3-4bags/min(5-50kg/bag) |

| Power | 2.2kw |

| Dimension | 2*0.8*2.6m |

Leave A Comment