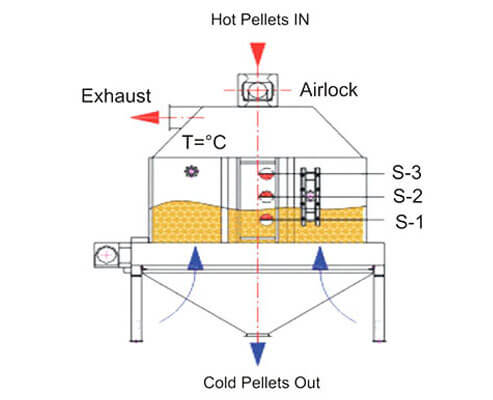

Introduction to Counterflow Wood Pellet Cooler

Being one necessity in large capacity biomass pellets and wood briquettes production line, wood pellet cooler adopts counter flow cooling principle to cool pellets rationally and evenly without cracking or breaking the pellets, so as to produce high quality biomass fuel production. Counterflow wood pellet cooler has been preferred by many countries nowadays for its stable performance, economic space occupation and easy operation.

Why Use Counterflow Wood Pellet Cooler?

1.When wood pellets are discharged from pellet mill, they are with high moisture content of about 16% and high temperature degree of about 70-90℃, after cooling the moisture can be lowed to no more than 12.5% with temperature to 3-5℃ higher than room temperature, thus making pellets convenient for storage and transportation.

2.With wood pellet cooler, labor drying can be largely reduced and low breakage rate can also be realized.

3.Counterflow wood pellet cooler can largely reduce the cost for its continuous working efficiency and free from weather condition.

4.No bird’s stealing or non-staff contact can avoid cross contamination.

Characteristics of Counterflow Wood Pellet Cooler

1.Counterflow wood pellet cooler adopts counter flow cooling principle to cool down pellets without direct contact between cold air and hot materials, thus can avoid the surface cracking of pellets.

2.Cooling chamber adopts the latest design of the octagonal type with no dead angle.

3.Counterflow wood pellet cooler has remarkable cooling effect for its adopting of air-closed materials feeder with large inlet wind area.

4.Discharging device employs slide valve reciprocating type, stable and reliable in operation, less residue.

5.Easy operation, low energy cost, stable performance.

6.Wide application. It can be used to cool various kinds of pellets.

7.Long service time, high automation and low noise.

Structure of Counterflow Wood Pellet Cooler

1. Observation window: When cooler machine working, we can observe the working condition.

2. Glass window: Glass material, easy observation and maintain.

3. Cooler motor: China famous motor and can be customized to Siemens motor.

4. Air Locker: Air locker controlling the air fan of cyclone.

5. Air Fan: air fan supply wind power for the cyclone and cooler machine.

6. Hydraulic system: help to open and reload the cooled pellets from the machine.

Technical parameter of Counterflow Wood Pellet Cooler

| Model | Capacity | Volume | Power |

| SKLB4 | 10t/h | 4m3 | 1.5+0.55kw |

| SKLB6 | 15t/h | 6m3 | 1.5+0.55kw |

| SKLB8 | 20t/h | 8m3 | 1.5+0.55+1.1kw |

| SKLB10 | 25t/h | 10m3 | 1.5+1.1+0.75kw |

| SKLB12 | 30t/h | 12m3 | 1.5+1.1+0.75kw |

Leave A Comment