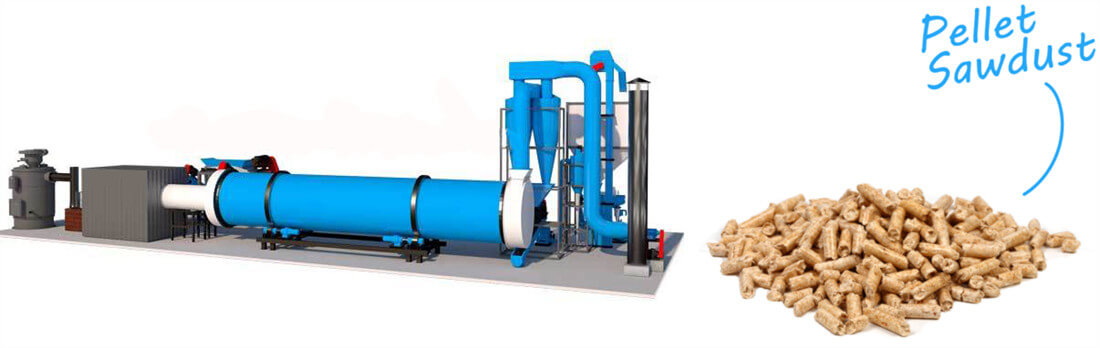

Customize 1T/H Sawdust Pellet Production Line for You

This sawdust pellet production line is specially designed for people who want to make sawdust pellets and with capacity requirement of 1t/h. * Specially designed for sawdust pellet production of 1t/h. * High quality with high output and stable operation. * Full automation of the production line, simple to operate.

1T/H Sawdust Pellet Plant Production Process

Sawdust → Drying → Pelletizing → Cooling → Packing → Packed Pellets

Main Equipment Related to 1T/H Sawdust Pellet Plant

1.Rotary Drum Dryer.

Being one important and indispensable drying equipment in sawdust pellets production line, rotary drum dryer can dry the moisture content contained in the raw material and make it become optimal for pelletizing. Rotary drum dryer is characterized by energy saving, high drying intensity, environmental friendly, large drying capacity, high heating efficiency and etc.

| Model | GX1200 | Capacity | 1-1.5t/h |

| Drum diameter | 1.2m | Drum length | 12m |

| Transmission power | 5.5kw | Air fan power | 11kw |

| Cyclone model | SKL1000 | Air lock power | 1.1kw |

2. MZLH420 Ring Die Wood Pellet Mill.

This wood pellet mill is produced after doing some research based on the features of biomass pelletizing. Ring die wood pellet mill is mainly used to make pellets from crushed raw materials such as sawdust, grass, straw, soybeans husk, rice husks, etc. This machine is usually equipped with 8mm, 10mm and 12mm ring dies because they are most favorable for combustion. Ring dies of other bore diameters can also be customizing according to customer demands.

| Model | MZLH420 | Capacity | 1t/h |

| Main motor power | 90kw | Screw feeder power | 2.2kw |

| Ring die inner diameter | 420mm | Ring die rotate speed | 150rpm |

| Roller outer diameter | 165mm | Pellet size | 6mm, 8mm, 10mm etc. |

| Roller quantity | 2 | Roller working temperature | ≤85℃ |

3. SKLN1.5 Sawdust Pellet Cooler

Wood pellet cooler is adopted to cooling the sawdust pellets after pelletizing. With sawdust pellet cooler, temperature of sawdust pellets can be reduced from 80-90℃ to about 3-5℃ above ambient temperature. Besides, moisture content of pellets can be reduced from 17%~18% to 12%~13%.

| Model | Cooling volume | Power |

| SKLN1.5 | 1.5m3 | 0.75kw |

| Production capacity | Cooling time | Air lock power |

| 3t/h | ≥6-10min | 1.1kw |

4. Sawdust Pellets Packing Machine

Pellets packing is the last step in pellets production process, however it is very important. Pellets packing machine can finish filling, weighting, delivering and sealing process automatically. Pellets packing machine can protect pellets from damp, corrosion and oxidation.

| Model | WDCS-50 |

| Capacity | 3-4bags/min(5-50kg/bag) |

| Power | 2.2kw |

| Dimension | 2*0.8*2.6m |