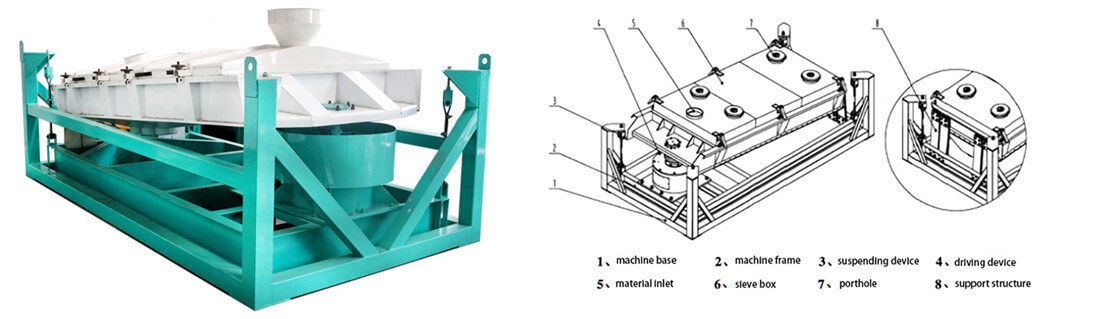

Rotary Feed Pellet Grading Sieve Introduction

Rotary feed pellet grading sieve is used for screening and grading pelleted feed. It can also be used for the previous cleaning of raw materials in feed plants and grading of the intermediate products after secondary grinding in large and medium-sized feed mills. Featured by fine sieving and grading effect, this rotary feed pellet grading sieve has two or three sieving layers. Depending on your demand, you can select a suitable one for you.

Features of Rotary Feed Pellet Grading Sieve

1.A strengthened engine base makes sure a balanced and steady operation.

2. Adopting advanced steel wire rope hanging structure to avoid the abrasion of the rope.

3. In order to get an excellent screening effect, the sieve combines three motion modes in the circular, oval, and linear way.

4. The screen adopts a special balancing way, so it is with less vibration and low noise.

5. The machine is equipped with a screen surface cleaning device, which has the advantages of large output, high screening efficiency, and low power consumption.

6. The inner streamline design prevents cross-contamination or material aggregation.

Working Principle of the Rotary Feed Pellets Screening Machine

This pellets grading sieve is made up of body frame, sieving boat, driving device, etc. For being separated from the fine powder and large pellets, the rotary grading sieve has two sieve layers. Small-sized feed pellets sieve quickly while the large-sized leave on the upper screen will move towards the discharge and be crushed again. During moving there is no agitation and vertical jump, so the smaller particles are always close to the screen surface and ready to sieve.

Rotary Feed Pellets Grading Sieve Machine Application

For getting uniform and qualified feed pellets, the rotary feed pellet grading sieve is a necessary step. This machine is mainly designed for cleaning the raw materials for pelleting, and it is also applied to sieve the unqualified large particles and powder or classifying of intermediate products after secondary grinding in large and medium scale feed mills. It is also suitable for sugar, food, chemical engineering, and grain industries.

Rotary Feed Pellet Grading Sieve Technical Parameters

| Model | Sieving Area(m²) | Power(kw) | Output(t/hr) |

| SFJH80 | 800*1600 | 1.5 | 3-8 t/hr |

| SFJH100 | 1000*2140 | 2.2 | 6-12 t/hr |

| SFJH125 | 1250*2500 | 3 | 8-15 t/hr |

| SFJH150 | 1500*2800 | 3 | 10-20 t/hr |