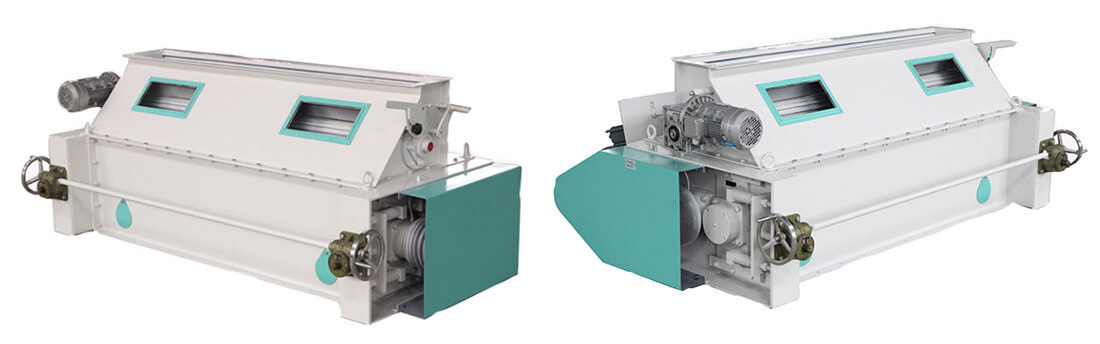

Feed Pellet Crumbler Introduction

The pellet crumbler is essential equipment in feed pellet production, which is dedicated to crumble large feed pellets into irregular small ones to meed different demands of different animals in different growth periods. It is suitable for crushing the feed pellets of various sizes to 0.6-1.5mm (fine tooth type) or 1-2.5mm (common tooth type). Small space occupation and optimal design of main drive ensure the high efficiency and perfect crushing effect, largely saving operating costs and highly flexible to meet the different demands of clients. We have both double-roller and three-roller type feed pellet roll crushers for your selection.

Features of Feed Pellet Roll Crusher

1. Compact structure, uniform crushing performance, and convenient adjustment of final particle size.

2. Unique feeding hopper ensures even feeding, and the feeding volume can be adjusted.

3. Rollers running in differential speed, the pellets are squeezed, cut and torn between the rollers, so as to achieve the ideal crushing effect.

4. Bypass device design, the materials that do not need to be crushed flow to bypass, and it can automatically shut down when the bypass flow through the travel switch.

5. Adopt narrow V-belt drive, smooth transmission, low noise, reliable and convenient operation.

6. Equipped with flange observation hole, convenient to operate and maintain.

7. Adopt the packing seal, prolong the service life of the bearing, and prevent ash leaking.

Feed Pellet Crumbler Application

Feed pellet roll crusher is designed for breaking large feed pellet materials into small ones, it is also suited to the soft materials. The double-roller type crusher is applied to crush poultry feed pellets. And the three-roller type one is more suitable for crushing aquatic feed pellets. Besides, it is also applied for the coarse/fine grinding in flour milling, oilseeds processing, and biomass fuel industry.

Feed Pellet Roll Crusher Technical Parameters

| Model | Y112M-4 | Y132S-4 | Y132M-4 | Y160M-4 |

| Roller size(dia.*length) | 150*800mm | 150*1000mm | 150*1500mm | 200*1700mm |

| Fast roller rotating speed | 725r/min | 725r/min | 725r/min | 725r/min |

| Slow roller rotating speed | 475r/min | 475r/min | 475r/min | 475r/min |

| Capacity | 2-4t/h | 3-6t/h | 5-10t/h | 8-12t/h |

| Power | 4kw | 5.5kw | 7.5/11kw | 15kw |