Ring Die Biomass Pellet Mill

Ring die biomass pellet machine, also known as wood pellet machine, that extrudes biomass material into pellets. The biomass particles have high density, high heat and no pollution.

Double Inlet Wood Crusher

High efficiency double-inlet wood crusher is mainly used for wood processing, especially for sawdust or wood pellets making. Capacity:0.8-3t/h.

Drum Wood Chipper

Drum wood chipper is used to chip raw materials into wood chips with uniform length, smooth incision and uniform thickness. Raw materials can be logs, branch wood, waste wood etc.

EFB Shredder

The empty fruit bunch shredder is to process the EFB into fiber and EFB fiber crushing machine is to crush the fiber into small pieces, and these two machines are the necessary equipment for EFB fiber pelletizing.

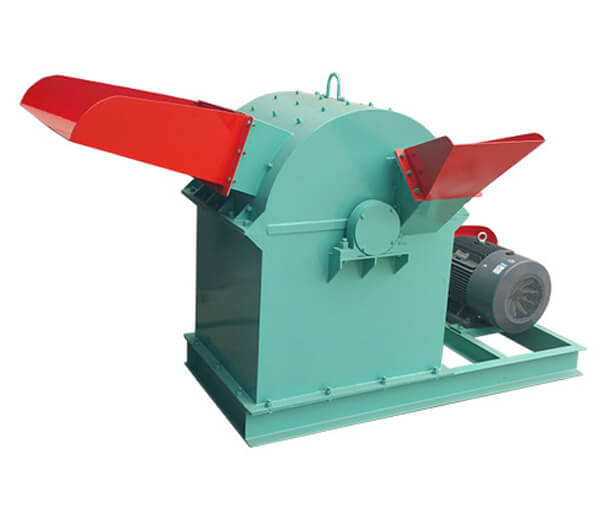

Wood Hammer Crusher Machine

Wood hammer crusher machine is mainly adopted to grind various kinds of biomass raw materials into the required fineness. After crushing, the product can be used for wood pellet, wood briquette etc.

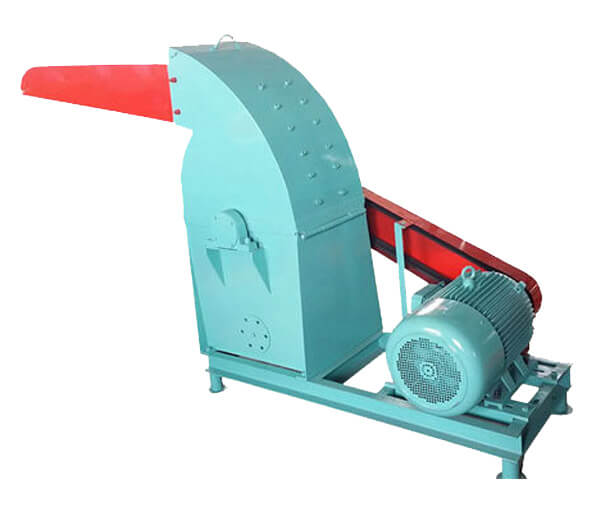

Wood Hammer Mill

Wood hammer mill is designed for crushing biomass raw materials into smaller and uniformed pieces with proper moisture. Suitable for medium or large sized wood pellet plants.

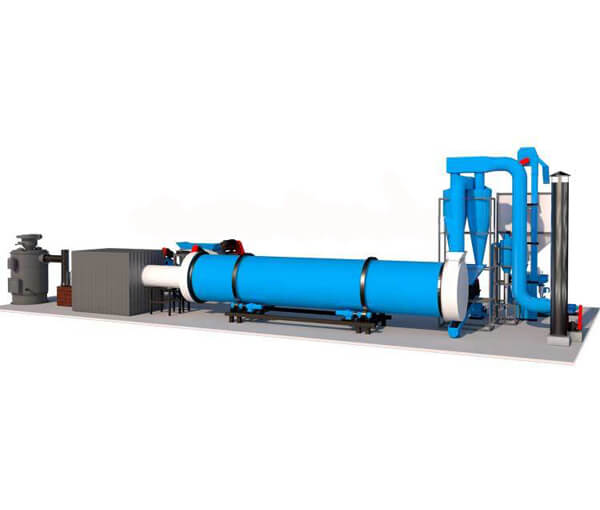

Rotary Drum Wood Dryer

With high efficiency and large capacity, the rotary wood dryer is suitable for drying the materials with high moisture content to increase biomass fuel efficiency of 5-15% and lower down emission.

Sawdust Pipe Dryer

Sawdust pipe / flash dryer is a small sawdust dryer compared with rotary sawdust dryer. Simple, efficient and inexpensive. Used for drying sawdust or other biomass residues.

Counterflow Wood Pellet Cooler

This wood pellet cooler adopts counter flow cooling principle to cool pellets rationally and evenly without cracking or breaking the pellets, so as to produce high quality biomass fuel production.

Wood Pellets Packaging Machine

Weighing and packing is the last procedure in wood pellet production process, which plays the indispensable role in improving wood pelletizing efficiency. High weighing accuracy, fast speed.

2T/H Giant King Grass Pellet Plant

Giant king grass pellet line is specifically used to make giant king grass pellets, consists of hammer mill, dryer, ring die pellet mill, pellet cooler etc.

1T/H Pine Wood Pellet Plant

This 1t/h pine wood pellet plant is very simple. The complete process includes wood crushing, drying, pelletizing, cooling and packaging, which is specially popular among the wood pellet manufacturers.

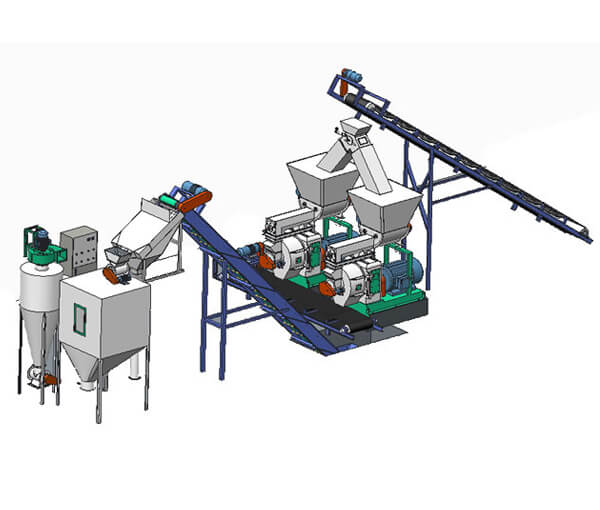

3T/H Sawdust Pellet Production Line

This complete sawdust pellet production line is designed for industrial use to make biomass pellets from any types of sawdust with capacity of 3t/h.

500kg/h Coconut Shell Pellet Line

From crushing, drying, pelletizing to cooling and packaging, this 500kg/h coconut shell pellet plant can process coconut shell into biomass pellets.

800-1000kg/h Straw Pellet Plant

800-1000kg/h straw pellet production line can make full use of crop waste, such as corn straw, rice straw, wheat straw and cotton straw to make pellets.

1T/H Sawdust Pellet Plant

This sawdust pellet production line is specially designed for people who want to make sawdust pellets and with capacity requirement of 1t/h. High output, stable operation and high efficiency.

2T/H Pine Wood Pellet Plant

For this 2t/h pine wood pellet plant, each step must be carried out with care. The whole procedures include pine wood debarking, chipping, drying, crushing, pelletizing, cooling&sieving and packaging.

1.5T/H Palm Waste Biomass Pellet Plant

With this 1.5t/h palm waste biomass pellet production line, you can make palm wastes into EFB pellets, PKS pellets, etc. It is suitable for small or medium palm oil processing factory.

1.5T/H Olive Pomace Pellet Plant

Olive pomace pellet plant is special designed for the recycling of industrial by-product obtained from the extraction of olive oil. We can also customize the pomace pellet plant with other capacities.

2T/H Olive Pomace Pellet Plant

Thanks to the excellent suitability for combustion, olive pomace becomes a superior raw material for fuel pellets. Pomace pellet plant is provided here with high efficiency but low energy consumption.

4T/H Coconut Shell Pellet Plant

The main machines of 4t/h coconut shell pellet plant are wood hammer crusher, rotary drum dryer, pelletizer, cooling machine, packing machine. It is suitable for medium or large pellet factories.

3T/H Giant King Grass Pellet Production Line

This giant king grass pellet plant is mainly equipped with wood chipper machine, rotary drum dryer, hammer mill, ring die pellet mill, pellet cooling and packing machine. Capacity is 3t/h.

2T/H Straw Pellet Production Line

2t/h straw pellet production line is making use of various kinds of waste straw to make biomass pellets, such as corn straw, rice straw, wheat straw and cotton straw etc.

4-5T/H Palm Biomass Waste Pellet Plant

This 4-5t/h palm biomass waste pellet production line is specially designed for making biomass pellets from palm wastes like EFB, PKS, OPF, OPT and OPMF etc. High efficiency and stable work.

Water Drop Wood Hammer Mill

Used to crush wide range of materials into smaller particles, water drop wood hammer mill has advanced structure, quality components, high efficiency, steady operation and long lifetime.