At present, biofuel wood pellet production has been more and more popular. It’s not only a project beneficial for environment and energy development, but also a perfect way to make high profits from various wastes. 500kg/h coconut shell pellet line a pipelining production including not only pelletizing but also pre-processed crushing and drying as well as reprocessed cooling and packing. Machines applied here are wood hammer mill, wood dryer, biomass pellet mill, biomass wood pellet cooler and biofuel wood pellet packing machine.

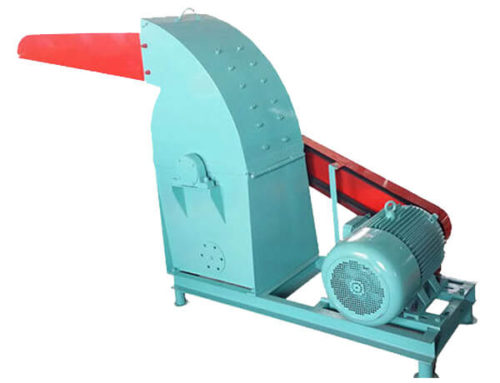

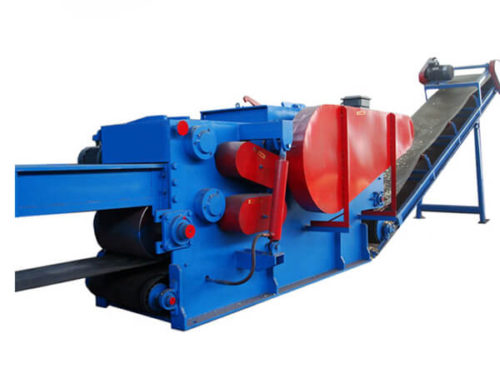

1. Coconut Shell Crushing

Biomass pellet mill requires the size of raw materials to be less than 5mm, so before further processing, coconut shells should be crushed into standard dimension first. Two types of wood hammer mills are available: electric and diesel. In this line, we choose HM 400 electric wood hammer mill.

Driven by a motor, electric wood hammer mill can be used to process coconut shells as well as other wood or biomass materials. For example, wood chip, wood bark, wood branch, corn stalk and wheat straw etc.

| Model | HM400 |

| Power | 11kw |

| Capacity | 600-800kg/h |

| Dimension | 1250*650*1000mm |

| Weight | 450kg |

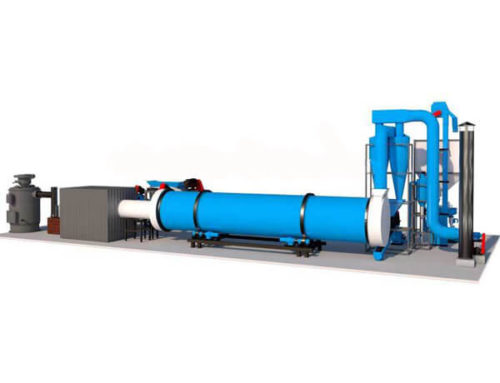

2. Drying

Size is not the only factor affecting the operation of biomass pellet mill, because raw materials can be so dry or so wet that produced biofuel pellets should be prone to breakage and looseness. No matter which category the materials belong to, their moisture content should be controlled within 12%-18%.

The drying machine used for 500kg/h coconut shell pellet line is airflow wood dryer which consists of heater, feeder, drying tube, cyclone separator and blower. The following information shows its working steps for drying coconut shells:

* Use wood feeder to feed coconut shells into drying tube.

* Use air heater to heat airflow.

* Use blower to deliver the heated airflow into drying tube where it will produce impulse. As a result, the touch area between coconut shells and airflow will be enlarged and the drying speed will be accelerated.

* After enough touch time, the dried coconut shells will be separated by cyclone and discharged for further processing.

| Model | TRM—QLHG36 |

| Power | 7.5kw |

| Capacity | 500-700kg/h |

| Reduced moisture | 15%-25% |

3. Pelletizing

As the soul part of biofuel production line, biomass pellet mill is mainly composed of roller and die which will produce extrusion and friction to coconut shells and change their shapes. The reshaped coconut shells are then squeezed out through the holes designed on pellet die. According to capacity and appearance, biomass pellet mill is classified into ring die type and flat die type. Concretely, You can either use one set of MZLH350 ring or one set of WPLM400 flat for the production of 500kg/h coconut shell pellet line

|

|

◊Ring die biomass pellet mill

With large capacity ranging from 0.6t/h to 4t/h, ring die biomass pellet mill has horizontal die and fast production rate. The processing amount changes in virtue of its changeable rollers.

◊Flat die biomass pellet mill

Compared with ring die type, the capacity of flat die biomass pellet mill is smaller yet wider, 40kg/h-1800kg/h. It’s suitable for relatively smaller quantities of raw materials. Same as biomass wood hammer mill, flat die biomass pellet mill can be classified into electric and diesel type according to applied engines.

Parameters of biomass pellet mill for 500kg/h coconut shell pellet line

| Model | MZLH350 | WPLM400 |

| Engine | Electric | |

| Capacity | 0.5t/h | 400-500kg/h |

| Main Power | 55kw | 30kw |

| Inner Diameter of Die | 350mm | 400mm |

| Pellet Size | 6, 8,10, 12mm etc. | |

4. Cooling

The finished products of coconut shell pellet line can reach to 90-95℃,so a biomass wood pellet cooler is required for fear that malfunction should happen to subsequent equipment. From bottom to top, dry air with room temperature is sent into the cooling chamber where produced coconut shell pellets have been spread evenly. After enough touch between the two of them, heat transfer is realized and coconut shell pellets are cooled to 3 ~ 5℃.

*Adopting counter flow cooling principle, preventing cracking of pellets and speeding up working efficiency.

*Wide range of large capacity, ranging from 3t/h to 30t/h.

*Advanced rotating structure, spreading coconut shell pellets evenly.

| Model | Cooling volume | Power |

| SKLN1.5 | 1.5m3 | 0.75kw |

| Production capacity | Cooling time | Air lock power |

| 3t/h | ≥6-10min | 1.1kw |

5. Packing

After all the above procedures, end products made from coconut shell pellet line should be properly packed in order to fast and convenient storage and transportation can be realized. The biofuel wood pellet packing machine adopted here works under full vacuum atmosphere which prevents dust and moisture from entering. Besides, equipped weighing devices can make the package reach standard level.

| Model | WDCS-50 |

| Capacity | 3-4bags/min(5-50kg/bag) |

| Power | 2.2kw |

| Dimension | 2*0.8*2.6m |