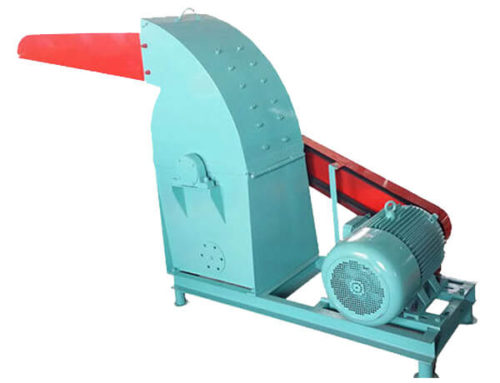

Wood Hammer Mill Introduction

Wood hammer mill is necessary in many sections. It is designed for crushing biomass raw materials into smaller and uniformed pieces with proper moisture. Taking wood pellet as an example, not all materials can be made into pellets directly when the raw material is larger than 5mm, then you need the wood hammer mill to crush them smaller. After that, you can make further processing. Also it can be used for crushing hard wood and soft wood, milling grain, shredding paper.

Features of Wood Hammer Mill

1. Compact structure, high efficiency, less wearing parts and beautiful design.

2. Adopting new technology to make sure hammer wear-resisting and impact resistant since hammer is easy to wear out.

3. No dust pollution due to the closed crushing system.

4. Environment friendly, convenient operation, high abrasion resistance, labor and time saving and low energy consumption.

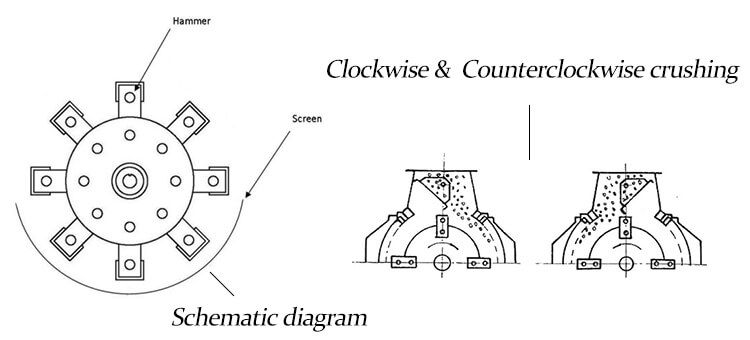

Working Principle of Wood Hammer Mill

This hammer mill consists of various beaters, they rotate at high speed in the grinding chamber. When the raw materials are delivered into the wood hammer mill, they are impacted and compressed by high speed rotary hammers. With the rotating hammers, these crushed materials are cut repeatedly in a short period. At last, the crushed materials are squeezed out from the under hole. Furthermore, you can adjust the clearance between beaters and screens to get different sized products.

Wood Hammer Mill Technical Parameters

| Model | FSP56*36 | FSP56*40 | FSP60*30 | FSP60*45 | FSP60*60 | FSP60*75 | FSP112*40 |

| Capacity(t/h) | 2.5—5 | 4—7 | 2—5.5 | 5—9 | 6—10 | 8—13 | 12—22 |

| Diameter of rotor(mm) | 560 | 560 | 600 | 600 | 600 | 600 | 1120 |

| Width of chamber(mm) | 360 | 400 | 300 | 450 | 600 | 750 | 400 |

| Hammer quantity | 20 | 24 | 24 | 44 | 48 | 60 | 40 |

| Speed of rotor(r/min) | 2980 | 2980 | 2980 | 2980 | 2980 | 2980 | 1440 |

| Power(kw) | 18.5/22 | 30/37 | 18.5/22 | 45/55 | 75/90 | 90/110 | 90/110 |

Leave A Comment