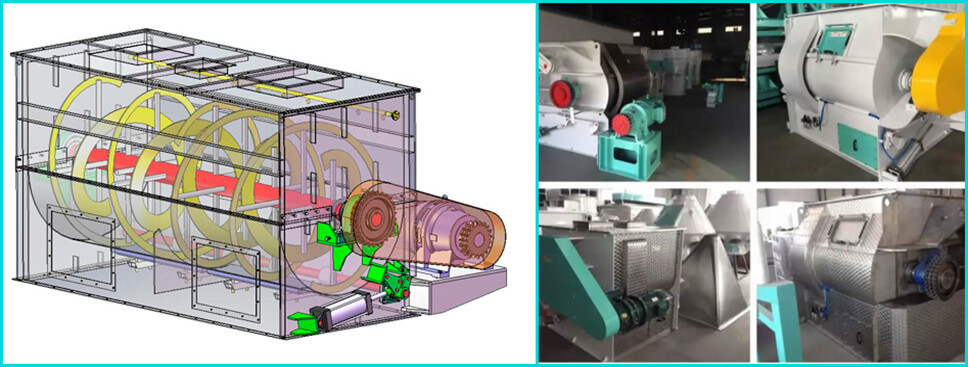

Feed Ribbon Blender Introduction

The SLHY series feed ribbon blender is a mature type machine widely used in feed plant for mixing the powder materials to ensure the quality of compound feed. During the mixing process, you can add the liquids or nutrients that the animal needs to the grain powder, making the feed pellets more nutritional. The ribbon mixer can also be used for mixing chemical products, such as compound fertilizer, pesticide, additive, health care products, etc. especially suitable for the viscous material mixing.

Main Characteristics of Feed Ribbon Mixer

1. Optimal designed bidirectional ribbon rotor, gentle mixing process, high uniformity without segregation.

2. Short mixing time per batch, large discharging door assures fast material discharging and less residue.

3. Stable transmission and little abrasion. Various machine types including carbon steel, stainless steel, composite materials and others for your choice.

4. Multiple spraying atomizer can be equipped to add various liquids.

5. Easy and convenient to maintain.

Feed Ribbon Blender Working Principle

A ribbon agitator consists of a set of inner and outer helical blades. When the ribbon blender works, the outer ribbon pushes the materials from both sides to the center of the barrel, while the inner ribbon pushes the materials from the center to both sides of the barrel, which is the most effective design of ribbon layout. More vortexes can be formed during the materials flow, thus accelerating the mixing speed and improving the mixing uniformity.

Ribbon Feed Blender Technical Data

| Model | Effective Volume | Each Batch Volume | Each Batch Mixing Time | Uniformity | Power |

| SLHY1 | 1m3 | 500kg | 3-6min | CV%≤7 | 11kw |

| SLHY2 | 2m3 | 1000kg | 3-6min | CV%≤7 | 18.5kw |

| SLHY4 | 4m3 | 2000kg | 3-6min | CV%≤7 | 30kw |

| SLHY6 | 6m3 | 3000kg | 3-6min | CV%≤7 | 37kw |

| SLHY8 | 8m3 | 4000kg | 3-6min | CV%≤7 | 45kw |